Page 33 - Журнал Sozvezdye Review - «СОЗВЕЗДИЕ» #38

P. 33

Alongside with repairs, the team have expertise in

modernization and conversion of ships. Some of the

projects use customized design developed by the com-

pany.

“The geography of our clients is expanding,” says An-

ton Krushelnitsky. “In addition to the companies based

Arkhangelsk Oblast (Northern Shipping Company, Arc-

tic Shipping Company, Northern Inland Shipping Com-

pany, Bunker Company Arkhangelsk, Trans-Fleet), we

now have clients based in other regions (Khatanga MTP,

Valkur, Pomor-Service, among others). I can say that we

now serve as a maintenance provider to the Arctic coast-

al fleet. Our capacity allows for the repairs to be done on

various types of ships. Also, our teams can travel to per-

form repairs onsite. Our growing performance enables

our upgrading plans, which include modernization of

the premises and purchase of machine tools and other

equipment. One recent acquisition is the mobile painting

unit for use at customer sites. Since this winter, we are

licensed for ship breaking and disposal. We have a ded-

icated team for this and equipment. Importantly, none

of the purchases have been made using borrowed funds.

We invest our profits in our growth.”

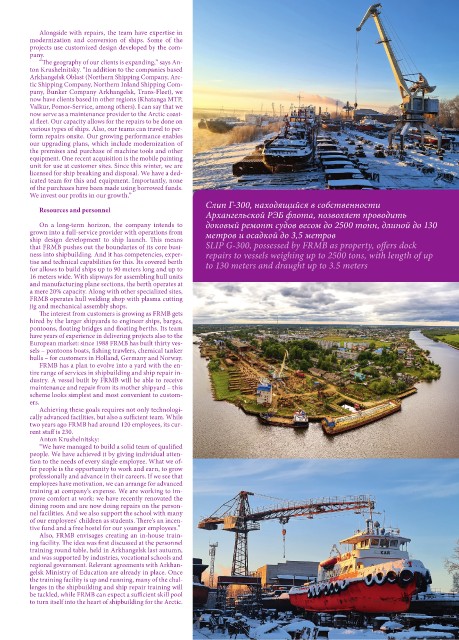

Слип Г-300, находящийся в собственности

Resources and personnel

Архангельской РЭБ флота, позволяет проводить

On a long-term horizon, the company intends to доковый ремонт судов весом до 2500 тонн, длиной до 130

grown into a full-service provider with operations from метров и осадкой до 3,5 метров

ship design development to ship launch. This means

that FRMB pushes out the boundaries of its core busi- SLIP G-300, possessed by FRMB as property, offers dock

ness into shipbuilding. And it has competencies, exper- repairs to vessels weighing up to 2500 tons, with length of up

tise and technical capabilities for this. Its covered berth to 130 meters and draught up to 3.5 meters

for allows to build ships up to 90 meters long and up to

16 meters wide. With slipways for assembling hull units

and manufacturing plane sections, the berth operates at

a mere 20% capacity. Along with other specialized sites,

FRMB operates hull welding shop with plasma cutting

jig and mechanical assembly shops.

The interest from customers is growing as FRMB gets

hired by the larger shipyards to engineer ships, barges,

pontoons, floating bridges and floating berths. Its team

have years of experience in delivering projects also to the

European market: since 1988 FRMB has built thirty ves-

sels – pontoons boats, fishing trawlers, chemical tanker

hulls – for customers in Holland, Germany and Norway.

FRMB has a plan to evolve into a yard with the en-

tire range of services in shipbuilding and ship repair in-

dustry. A vessel built by FRMB will be able to receive

maintenance and repair from its mother shipyard – this

scheme looks simplest and most convenient to custom-

ers.

Achieving these goals requires not only technologi-

cally advanced facilities, but also a sufficient team. While

two years ago FRMB had around 120 employees, its cur-

rent staff is 230.

Anton Krushelnitsky:

“We have managed to build a solid team of qualified

people. We have achieved it by giving individual atten-

tion to the needs of every single employee. What we of-

fer people is the opportunity to work and earn, to grow

professionally and advance in their careers. If we see that

employees have motivation, we can arrange for advanced

training at company’s expense. We are working to im-

prove comfort at work: we have recently renovated the

dining room and are now doing repairs on the person-

nel facilities. And we also support the school with many

of our employees’ children as students. There’s an incen-

tive fund and a free hostel for our younger employees.”

Also, FRMB envisages creating an in-house train-

ing facility. The idea was first discussed at the personnel

training round table, held in Arkhangelsk last autumn,

and was supported by industries, vocational schools and

regional government. Relevant agreements with Arkhan-

gelsk Ministry of Education are already in place. Once

the training facility is up and running, many of the chal-

lenges in the shipbuilding and ship repair training will

be tackled, while FRMB can expect a sufficient skill pool

to turn itself into the heart of shipbuilding for the Arctic.